News

Exhibition at MaterialenNL conference

04-12-2023

We will be showcasing our NanoMoi instrument at theMaterialenNL conference next week!

📅 Tuesday December 12

📍 Papendal, Arnhem

🌐 Preliminary programme

✍ Register here

Visit our booth at the exhibition floor to see a live demonstration, discuss the options for materials science Research & Development or get to know our spin-off company.

We're excited to visit this conference to connect with the materials science community where there are many applications for our instrument.

The MaterialenNL Conference is powered by:

NanoMoi featured in WUR video on data science!

15-11-2023

Watch this movie about data science at Wageningen University & Research to see the NanoMoi instrument live in action!

Article in JoVE on 3D-Printing!

04-09-2023

The first scientific article with NanoMoi instrument data has been published in the Journal of Visualized Experiments (JoVE), including informational and instructional videos! The publication titled "Real-Time Imaging of Bonding in 3D-Printed Layers" by Jesse Buijs, Raoul Fix, Hanne van der Kooij, and Thomas Kodger can be found on doi: 10.3791/65415 .

The article and videos explain how to use the NanoMoi instrument to visualize the melting and solidification of plastic during 3D-printing, which determines the object strength and surface quality.

The applications page is live

16-08-2023

Check out the latest addition to our website: the Applications page! On this page example applications and results for the NanoMoi instrument are showcased.

At the moment two applications are showcased: Solvent detection during restoration of oil paintings and recording drying profiles for coatings.

Other applications will be added as they become available, so stay tuned!

Maarten finishes his MSc thesis!

21-07-2023

Congratulations to Maarten Dols for finishing his MSc research thesis at the Physical Chemistry and Soft Matter group at Wageningen University and Research! Maarten was the first researcher to utilize the NanoMoi instrument for routine measurements.

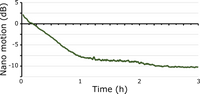

Maarten studied and characterized variations in the paint drying profiles as a result of internal and external factors. His findings demonstrated the significance of such measurements, as small variations in the humidity doubled the drying time, while the substrate's porosity had an eightfold effect! Maarten showcased his resourcefulness by validating the results thoroughly with a self-built automated scratch test.

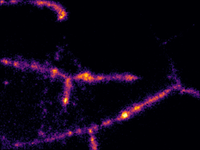

A sample result from Maarten's drying tests. The drying profile graph above shows the decreasing nano motion as the pigment particles slow down in the drying paint. After one hour the paint is touch-dry, the surface is non-stick. After roughly two hours, the paint is hard-dry throughout the whole layer. On the right a movie is shown of the drying front passing from right to left, just before two hours have passed.

Maarten did his thesis while NanoMoi was starting to take shape. We're very grateful for his significant contributions to this process. His contributions have left a lasting mark on our company as he designed the NanoMoi logo, photographed the instrument, designed pitch decks, and made connections for practical application of his results.

We wish Maarten all the best with the continuation of his career. Good luck with your internship to successfully finish your MSc in Molecular Life Sciences!

Introducing NanoMoi

20-07-2023

NanoMoi starts today as a Wageningen University & Research spin-off company! NanoMoi's mission is to democratize the scientific technology 'Laser Speckle Imaging' (LSI), making it widely accessible for various applications.

With the NanoMoi instrument, you can easily visualize nanoscopic motions to unravel dynamical processes inside materials and obtain highly detailed insights. Our technology enables you to characterize phase transitions like melting, drying, evaporation, crystallization and solidification, to precisely determine the exact time- and lengthscale of these events. Additionally, local deformations like fracture, stress and flow can be imaged in real-time to obtain highly detailed movies of the inhomogeneities.

NanoMoi will start activities in the field of art conservation, specifically the restoration of oil paintings. During the removal of old varnish, excess solvent can enter the paint layer of the artwork. Research has shown that NanoMoi can detect the increased motion of the pigment particles when solvent softens the paint. By detecting the solvent in the paint, we can help tailor the cleaning procedures to minimize the solvent exposure, ensuring the preservation of artworks for the generations to come.

To unlock its full potential, NanoMoi is actively developing diverse applications. Keep following our journey on this website and LinkedIn to stay up-to-date. If you are interested and want to know what NanoMoi can do for you, contact us!